Engineering serve

Technology and service oriented project model

Solve dust removal industry

The common problems of bag dust removal equipment

High resistancehigh efficiencyLow efficiencyLow lifeDifficult to maintainDust removal technology upgrading

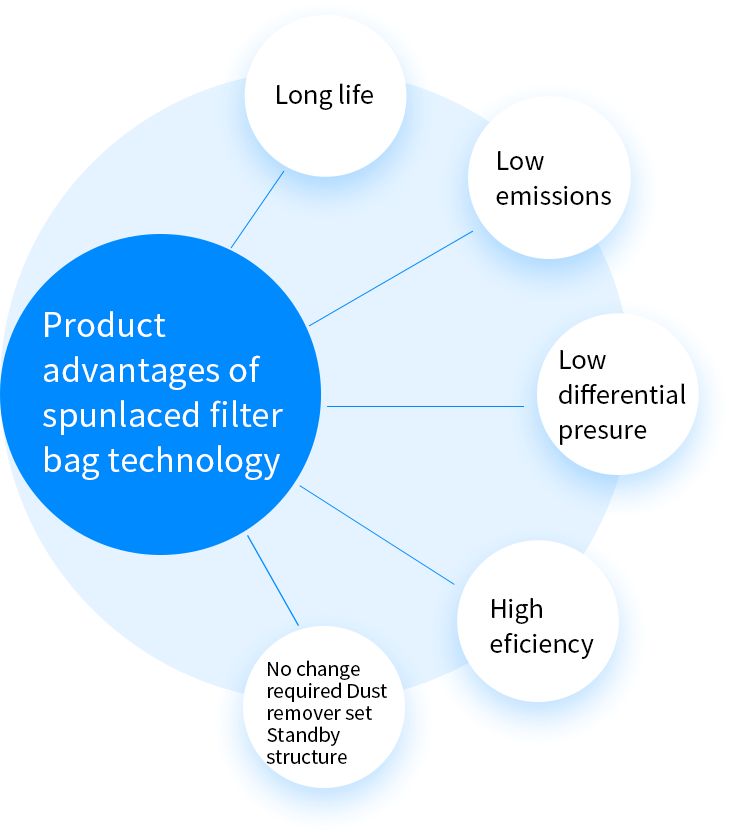

Filter element using Andrew's spool process filter material with surface dust collection efficiency (Hydrolox® and Hydrolox®HCE)

Aiming at the practical problems of the dust removal equipment in cement industry, such as long continuous operation time, short downtime and maintenance time, and limited renovation space, we provide a quick and effective overall solution

Case sharing

Bag Dust collector for cement Combined Grinding System (5000t/d)

| Project | Before transformation (filter bag) | Remarks after modification | |

| Dag dust collector No. 1 | Dag dust collector No. 2 | ||

| Dust collector body | / | No need to transform, correct deformation | No need to transform, correct deformation |

| Processing air volume | 200000m³/h | 240000m³/h | 240000m³/h |

| Operating temperature | |||

| Particulate matter composition | Cement | Cement | Cement |

| Inlet particulate concentration (g/Nm3) | |||

| Filter element type | Φ130X3048 filter-bag | Φ130X3048 filter-bag Φ130X1500 filter-bag | Φ130X3048 filter-bag |

| Number of filter elements | 2816个 | 2505+168个 | 2816个 |

| Diameter | 135mm | 135mm | 135mm |

| Plate thickness | 6mm | 6mm | 6mm |

| Individual element filtration area | 1.18m² | 1.18/0.54m² | 1.18m² |

| Filter area | 3322m² | 3047m² | 3322m² |

| Filter material | Polyester film covered needle felt | AID-PCS100HU1CHydrolox HCES punlace filter material | AID-PCS100HU1CHydrolox HCES punlace filter material |

| filtration velocity | 1m/min | 1.31m/min | 1.31m/min |

| Ash removal method | Air tank pulse injection | Air tank pulse injection | Air tank pulse injection |

| Injection pressure | 0.5-0.7MPa | 0.4-0.6MPa | 0.4-0.6MPa |

| Operating differential pressure | 2800-3600Pa | 1500-1700Pa | 1500-1700Pa |

| discharge | ≤30mg/m³ | ≤30mg/m³ | 7.1mg/m³ |

| 7.1mg/m³ | ≥12Months | 24-36Months | 24-36Months |